The world’s first megawatt-scale co-electrolyser for industrial production of syngas – the pre-cursor for green fuels - receives a Horizon 2020 funding amounting to EUR 5 million and will be coordinated by Professor Anne Hauch, DTU Energy, Technical University of Denmark. The MegaSyn project started April 1st and has a duration of 4 years.

The EU funding is granted to a consortium consisting of DTU Energy at the Technical University of Denmark, Sunfire (Electrolyzer Manufacturer), OMV (Oil, Gas & Chemicals Group), SMS group company Paul Wurth (Iron and Steel Industry Supplier) and Graz University of Technology. The MegaSyn project aims at demonstrating the large-scale industrial production of syngas (CO+H2) via co-electrolysis of CO2 and H2O. Syngas is the precursor for the production of green fuels or other chemicals in a Power-to-X process.

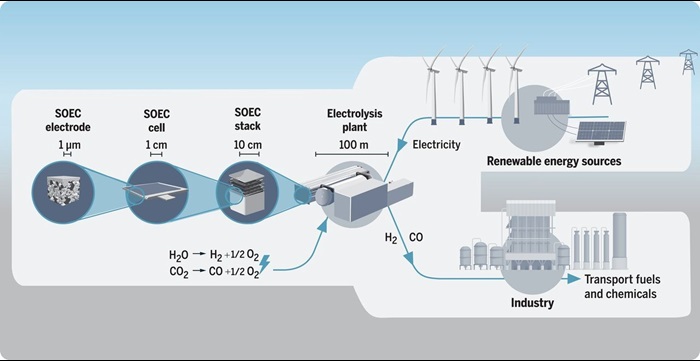

Firstly, the project focuses on producing the solid oxide electrolysis cells (SOEC), the stacks and modules and examine their performance and durability, as well as investigate gas stream quality. Secondly, the project will focus on operation of the demonstration plant in an industrial environment. The MegaSyn project will lift the SOEC co-electrolysis technology from TRL 5 to TRL 7 towards commercialisation.

With a research experience dating back to 2003, DTU Energy (Technical University of Denmark) is responsible for investigating degradation and lifetime aspects of the SOECs prior to and after the demonstration period. ‘After almost two decades of research, it’s fantastic to witness that the SOEC technology has reached a level to bring it further jointly with our partners in academia and industry. The project is receiving EUR 5 million from EU trusting the technology to be part of our future energy system,” says Professor Anne Hauch from DTU Energy.

The co-electrolysis process – the core of the Power-to-X plant: Using electricity from renewable energy sources, electrolysis cells are able to split water molecules into hydrogen and oxygen and convert CO2 into CO. This generates a synthesis gas, which is a mixture of hydrogen (H2) and carbon monoxide (CO). The synthesis gas can be further processed to produce various types of green fuels; the full process is an example of ‘Power-to-X’, where electricity is turned into fuels or chemicals.

Partners and funding: DTU Energy will ensure with their advanced facilities for electrochemical and microstructural test and characterisation that the cells and stacks are durable and efficient enough to guarantee the stable supply of synthesis gas, while the Austrian Graz University of Technology will examine the feed stream quality and its impact on the degradation of catalysts, single-cells and stacks. The German clean-tech company Sunfire, a leading player and manufacturer of electrolysers, is responsible for producing the SOEC cells, stacks and modules for the electrolyser, while Paul Wurth and OMV are industrial partners.

The consortium has received EUR 5 million from the Joint Undertaking Fuel Cells and Hydrogen under Horizon 2020 via the grant under grant agreement No 101007108. The JU receives support from the European Union’s Horizon 2020 research and innovation programme and Hydrogen Europe and Hydrogen Europe Research.

Figure from: "Recent advances in solid oxide cell technology for electrolysis”, Hauch, A., Küngas, R., Blennow, P., Hansen, A. B., Hansen, J. B., Mathiesen, B. V. & Mogensen, M. B., 2020, In: Science. 370, 6513, p. eaba6118-eaba6118